Are Neodymium Magnets Waterproof? How to Protect Them from Rust and Corrosion

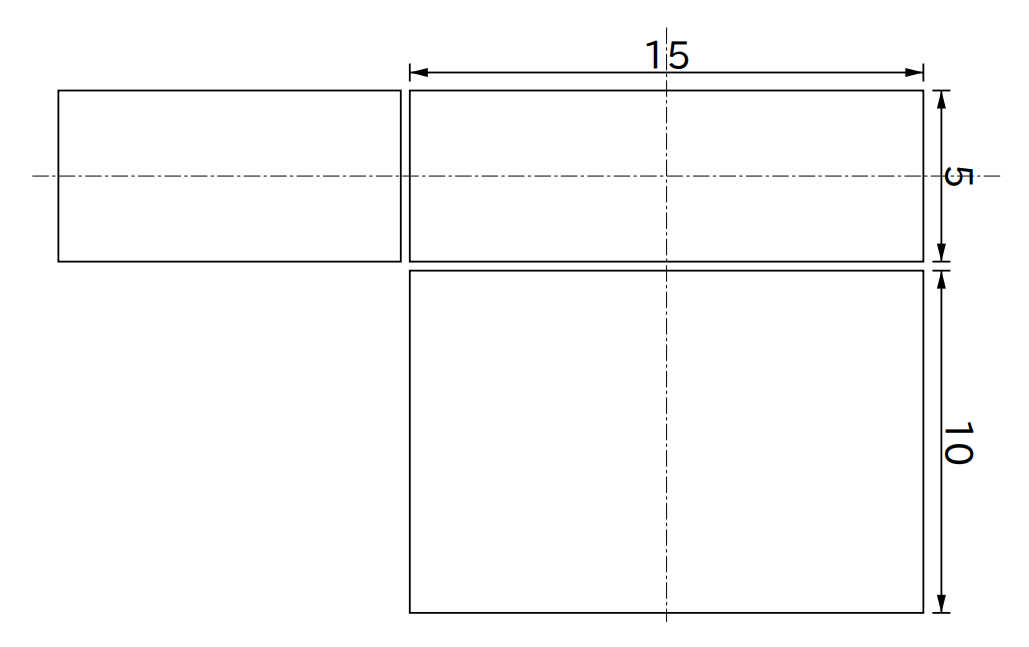

Neodymium magnets are the strongest commercially available magnets, widely used in industries, manufacturing, and everyday applications. But a common concern is whether these powerful neodymium magnets are waterproof and how they can be protected from rust and corrosion.

Are Neodymium Magnets Waterproof?

The short answer is no—neodymium magnets are not inherently waterproof. They are made from an alloy of neodymium, iron, and boron (NdFeB), and the iron content makes them highly susceptible to rust and corrosion when exposed to moisture.

Why Do Neodymium Magnets Rust?

Rust occurs when iron reacts with oxygen and moisture. Since neodymium magnets contain iron, exposure to water, humidity, or corrosive environments can lead to surface damage, weakening their magnetic strength over time.

How to Protect Neodymium Magnets from Rust and Corrosion

There are several ways to enhance the durability of neodymium magnets and extend their lifespan:

1. Coatings and Platings

Most industrial magnets come with protective coatings. Common options include:

- Nickel (Ni-Cu-Ni): A triple-layer coating that provides basic corrosion resistance.

- Epoxy: Magfine Corporation offers high-quality epoxy-coated neodymium magnets, providing superior moisture resistance. The epoxy layer creates an additional barrier against rust, making these magnets ideal for humid or wet environments.

- Nylon Coating: Magfine's nylon-coated magnets are designed for applications requiring both durability and enhanced protection against corrosion. The nylon layer improves wear resistance and prevents direct exposure to air and water.

- Gold or Zinc: Effective for applications needing aesthetic appeal and some resistance.

- Parylene: A thin, highly durable coating used in medical and high-tech applications.

2. Encapsulation in Waterproof Materials

For high-humidity environments, neodymium magnets can be enclosed in waterproof casings, such as plastic, stainless steel, or rubber. This is ideal for marine or outdoor applications.

3. Proper Storage

To prevent corrosion, store magnets in dry, temperature-controlled environments. Avoid direct exposure to water or chemicals.

4. Choosing Quality Neodymium Magnets

High-quality magnets in Canada from reputable suppliers like Magfine Corporation undergo stringent testing to ensure durability. Cheap, low-quality magnets often have poor coatings and corrode quickly.

Applications That Require Waterproofing

Some industries require neodymium magnets to be corrosion-resistant, including:

- Medical Devices: Encapsulated magnets for safe use inside the body.

- Marine Applications: Used in underwater sensors, fishing, and navigation tools.

- Outdoor Signage: Magnets in signage must withstand rain and humidity.

- Automotive Industry: Used in sensors, electric motors, and hybrid vehicle systems.

Find the Right Neodymium Magnet for Your Needs

At Magfine Corporation, we provide high-quality neodymium magnets for various industrial and commercial applications. Browse our online store to find corrosion-resistant options suitable for your needs.

Frequently Asked Questions (FAQ)

Can neodymium magnets be used underwater?

Standard neodymium magnets will corrode in water. However, waterproofed or encapsulated magnets can be used for underwater applications.

Do all neodymium magnets have a protective coating?

Most high-quality neodymium magnets have a protective coating, but not all. Always check specifications before purchasing.

How can I prevent my magnets from rusting?

Store them in a dry place, choose coated or encapsulated magnets, and avoid direct exposure to moisture.