Countersunk Block Magnets: Secure Mounting for Industrial and DIY Applications

When it comes to powerful and secure mounting solutions, countersunk block magnets are an excellent choice. Their unique design, featuring a pre-drilled hole for screws, makes them ideal for applications requiring a flush, reliable attachment. Whether in industrial machinery, furniture assembly, or home improvement projects, these magnets provide unparalleled strength and convenience.

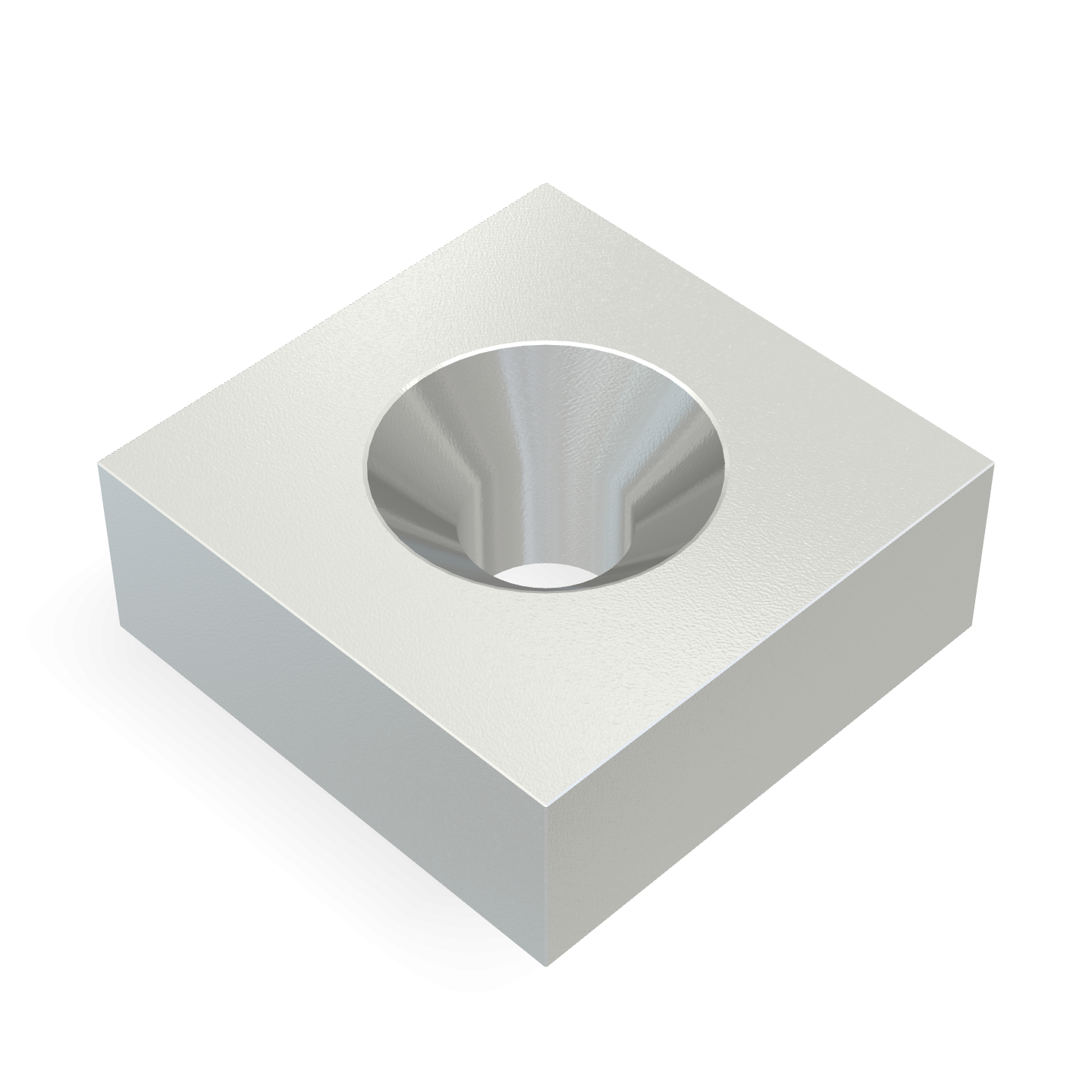

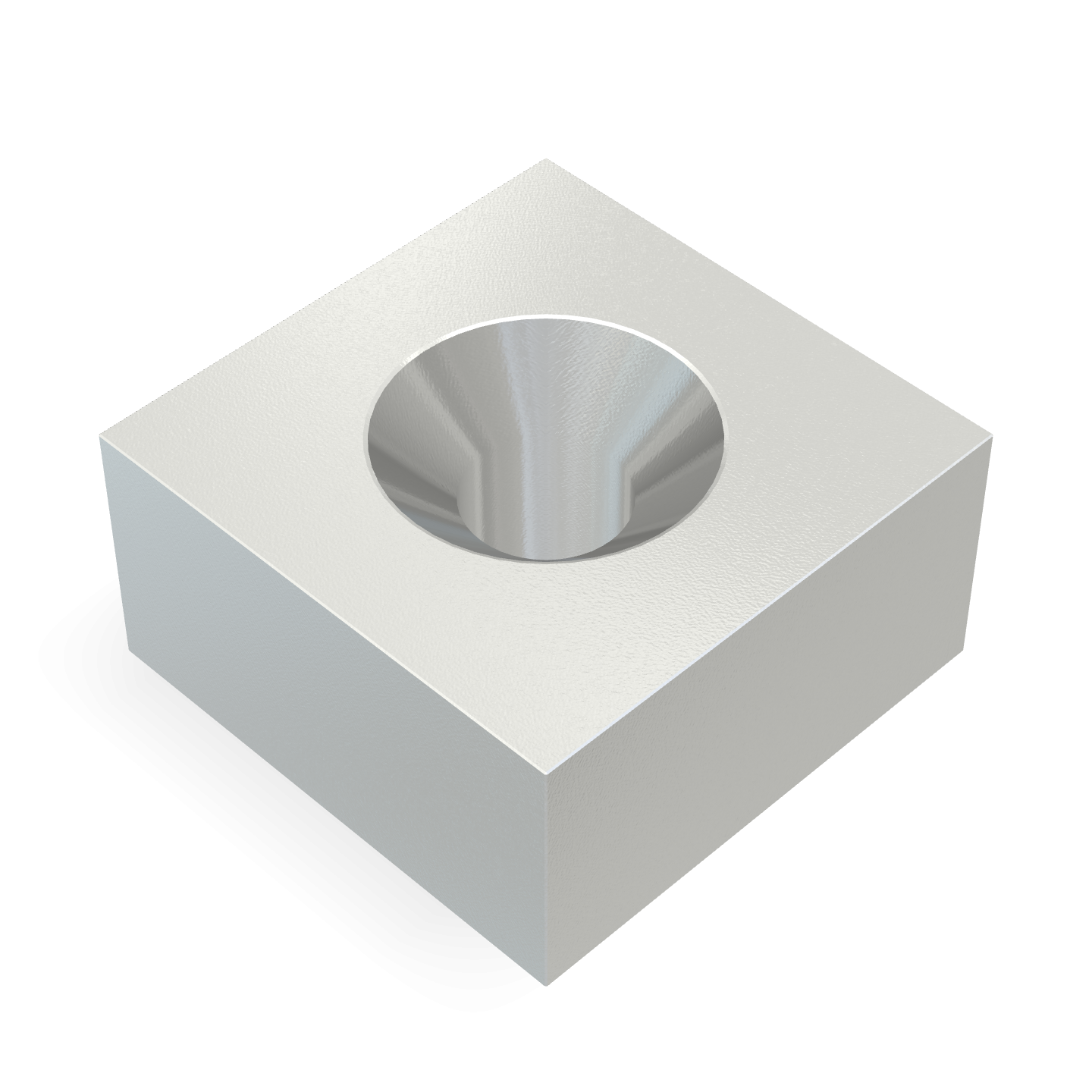

What Are Countersunk Block Magnets?

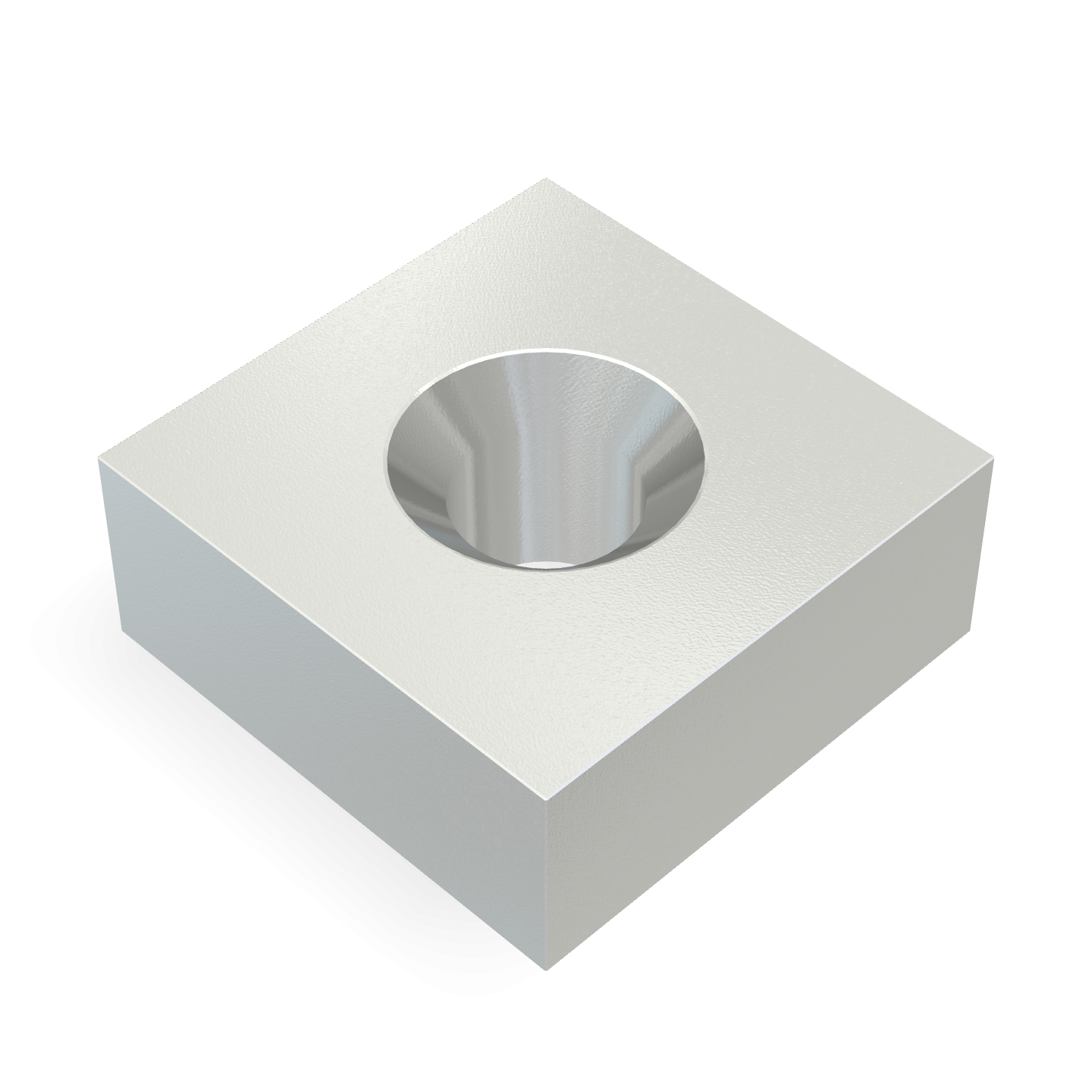

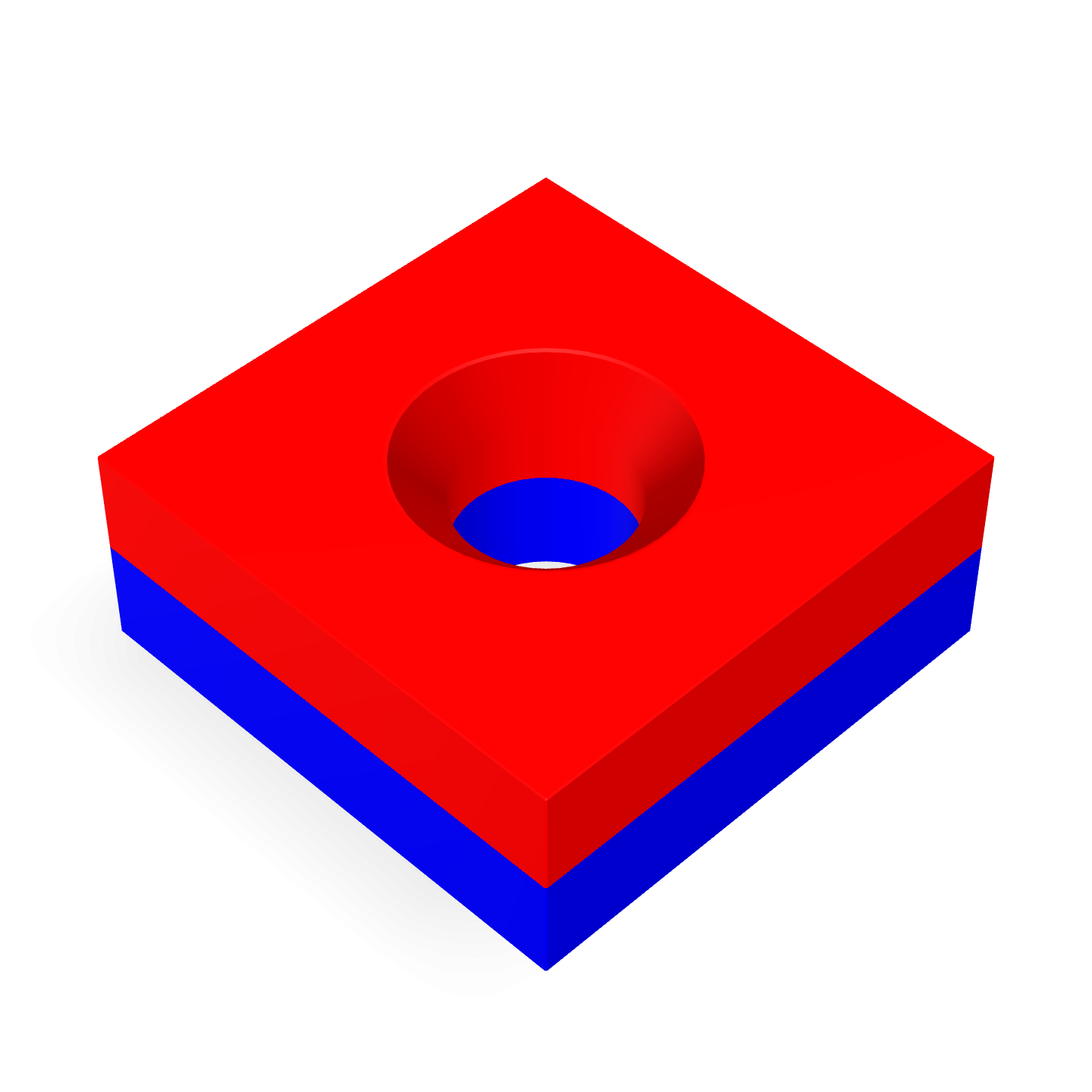

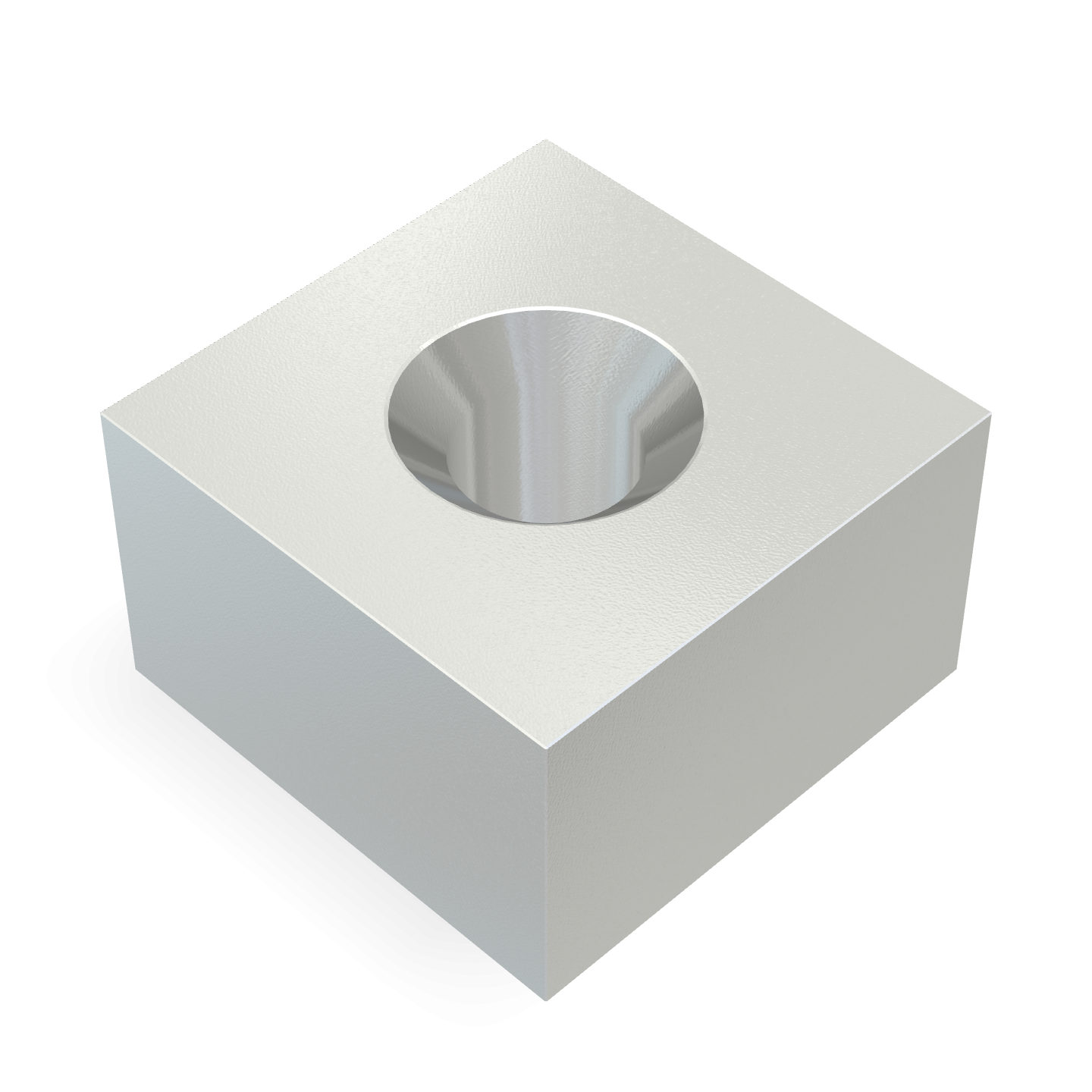

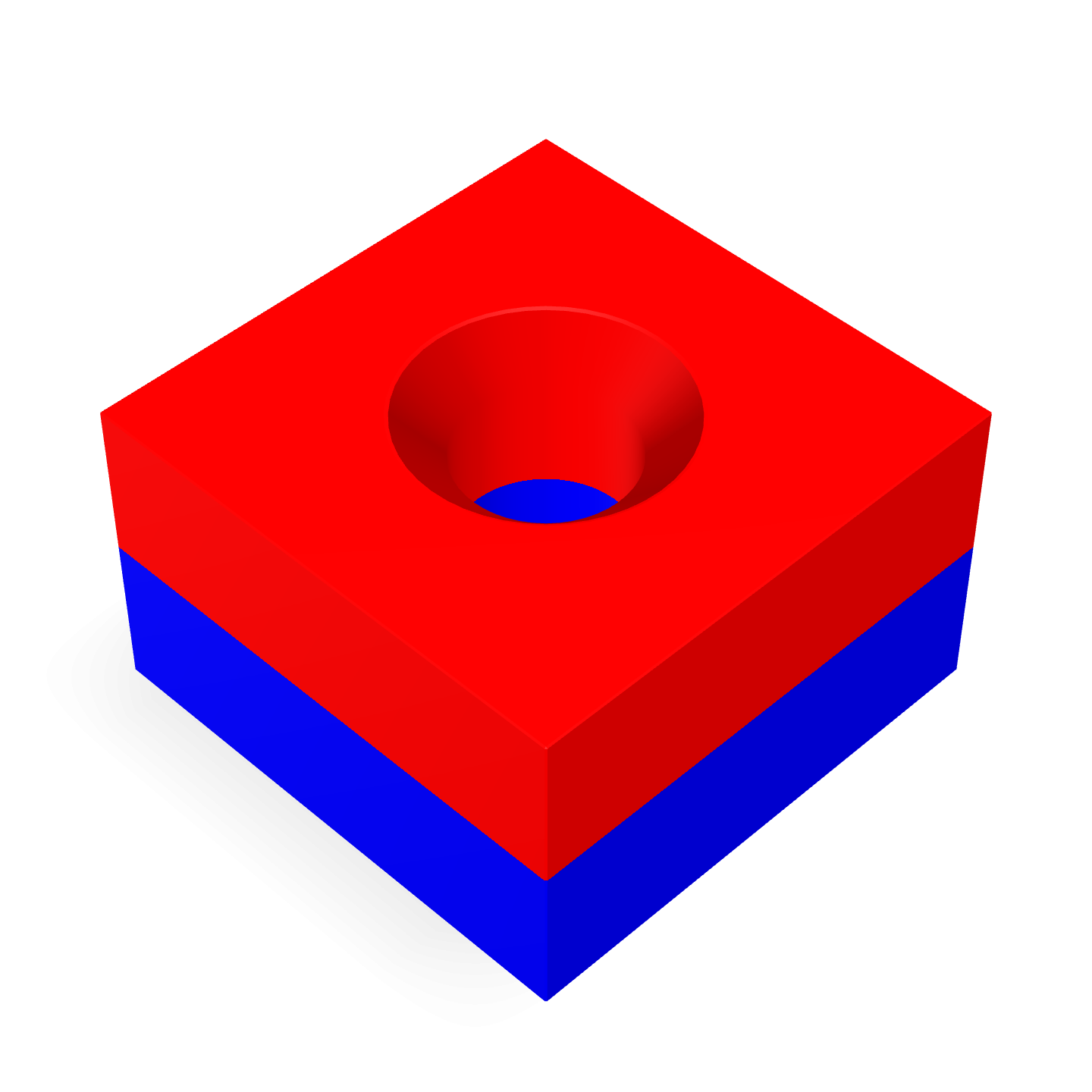

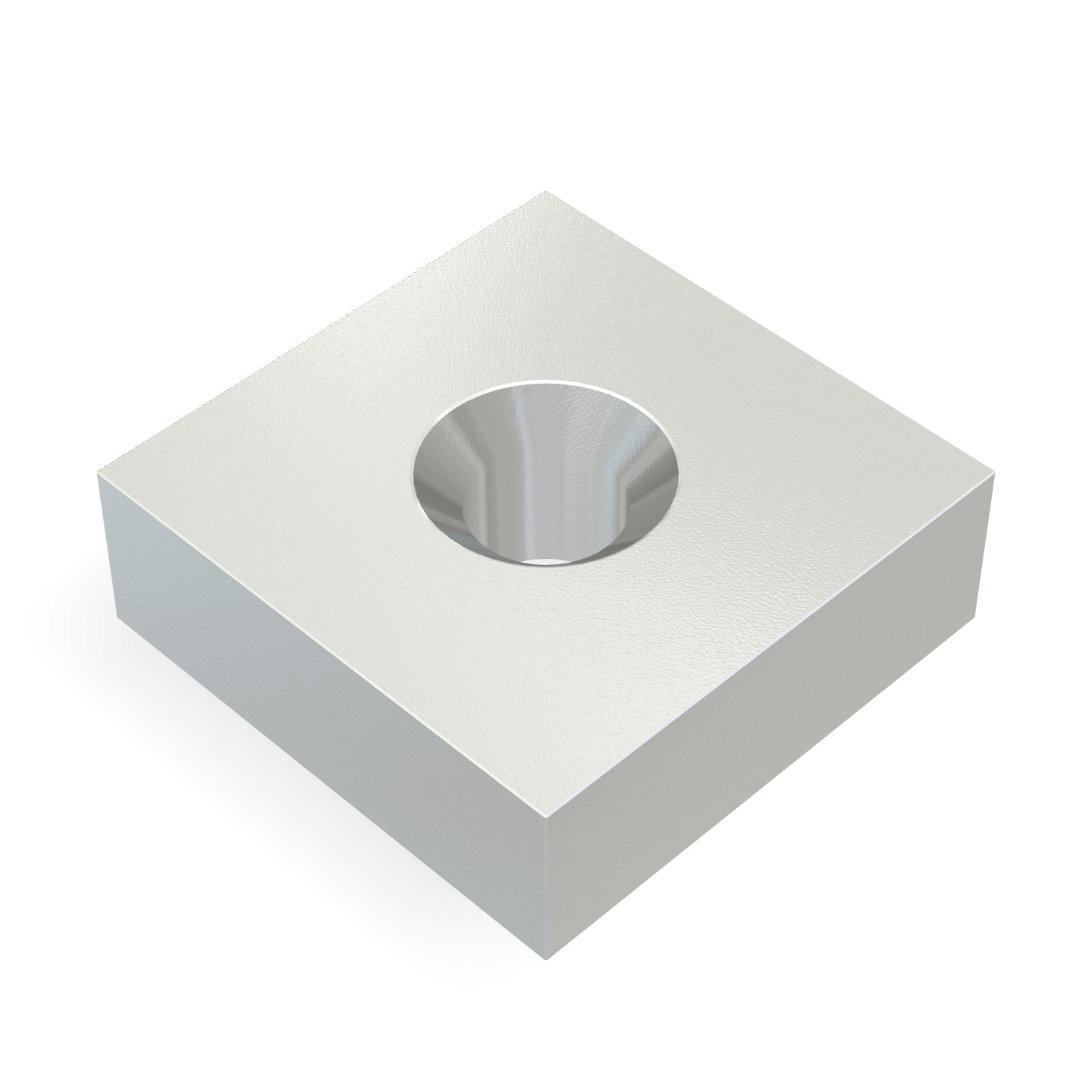

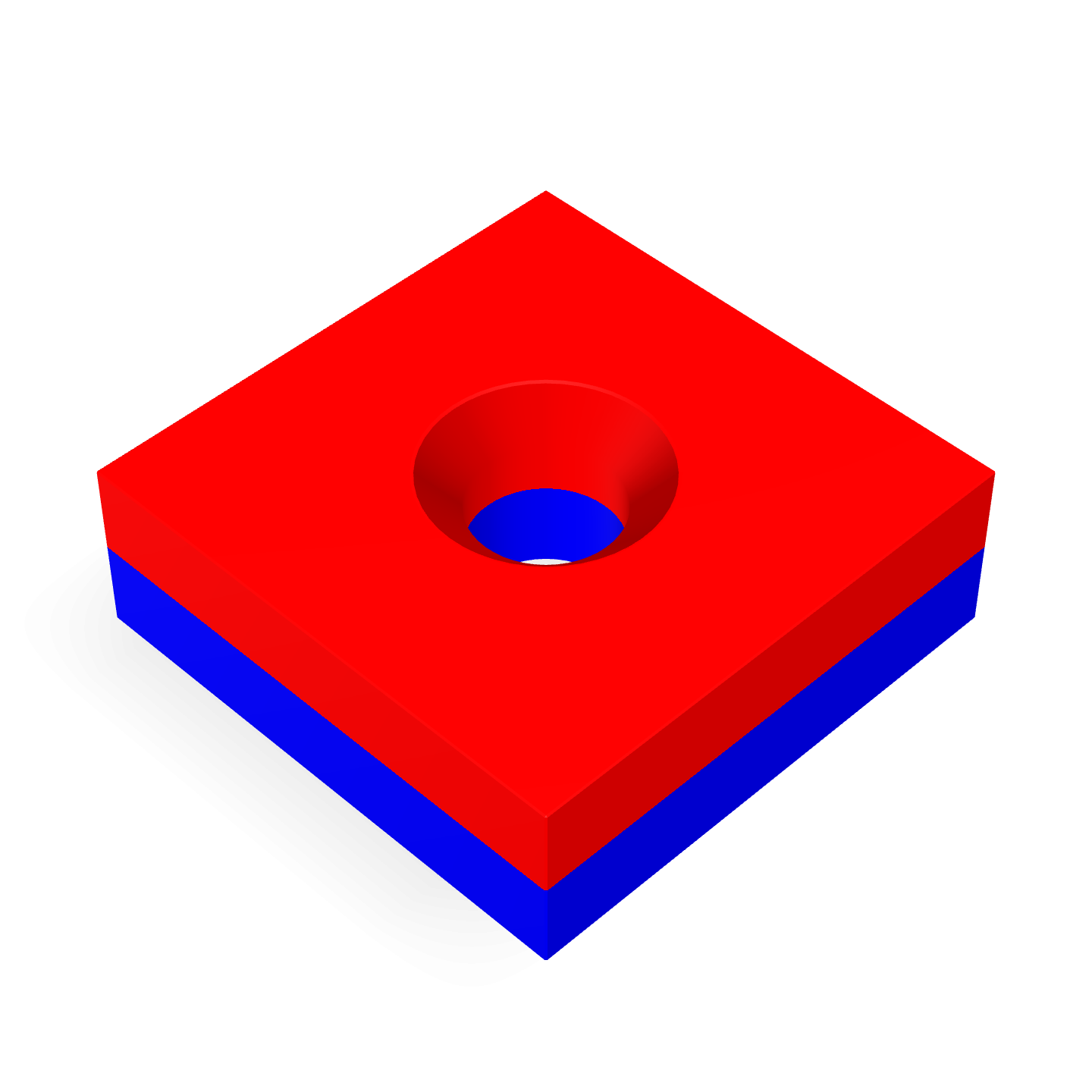

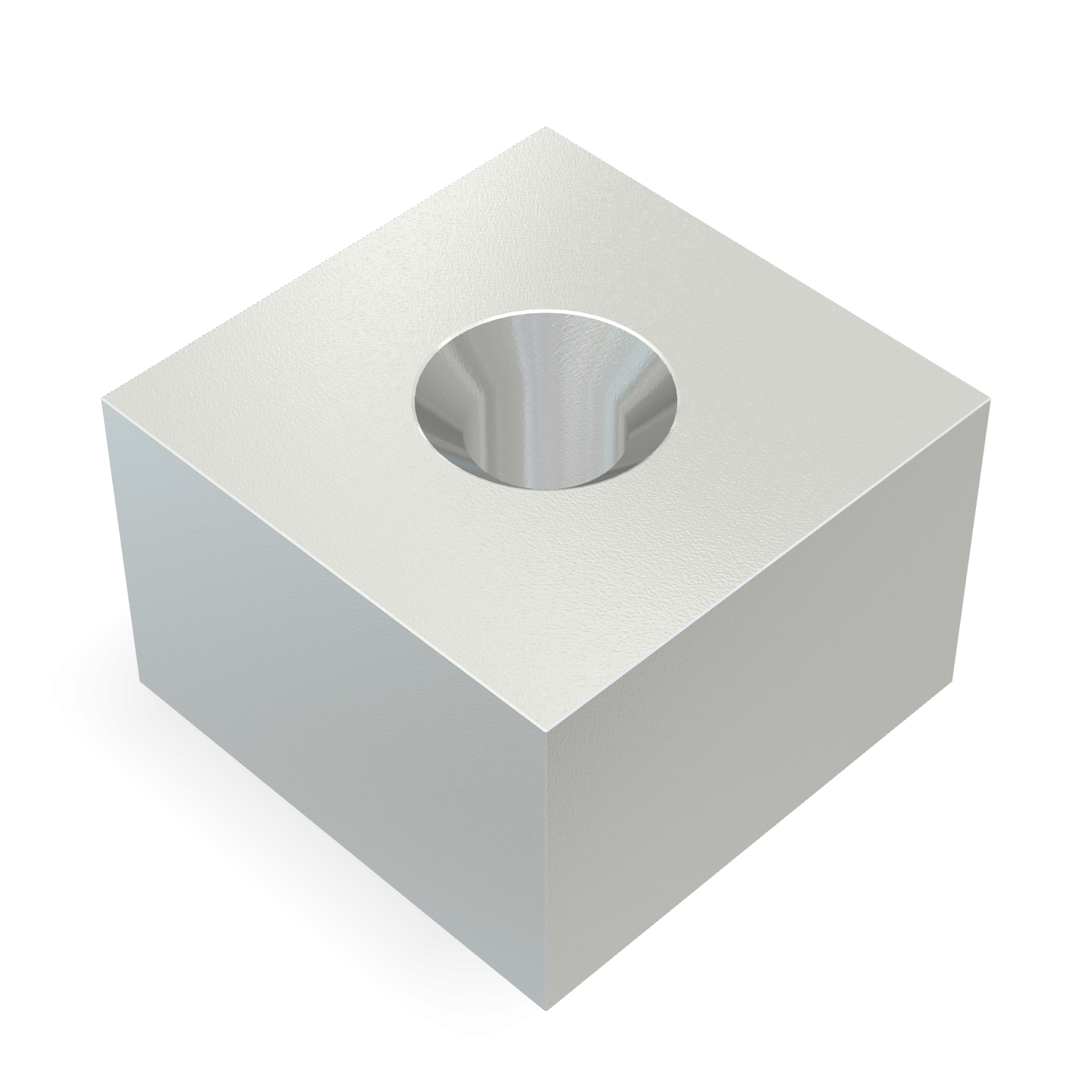

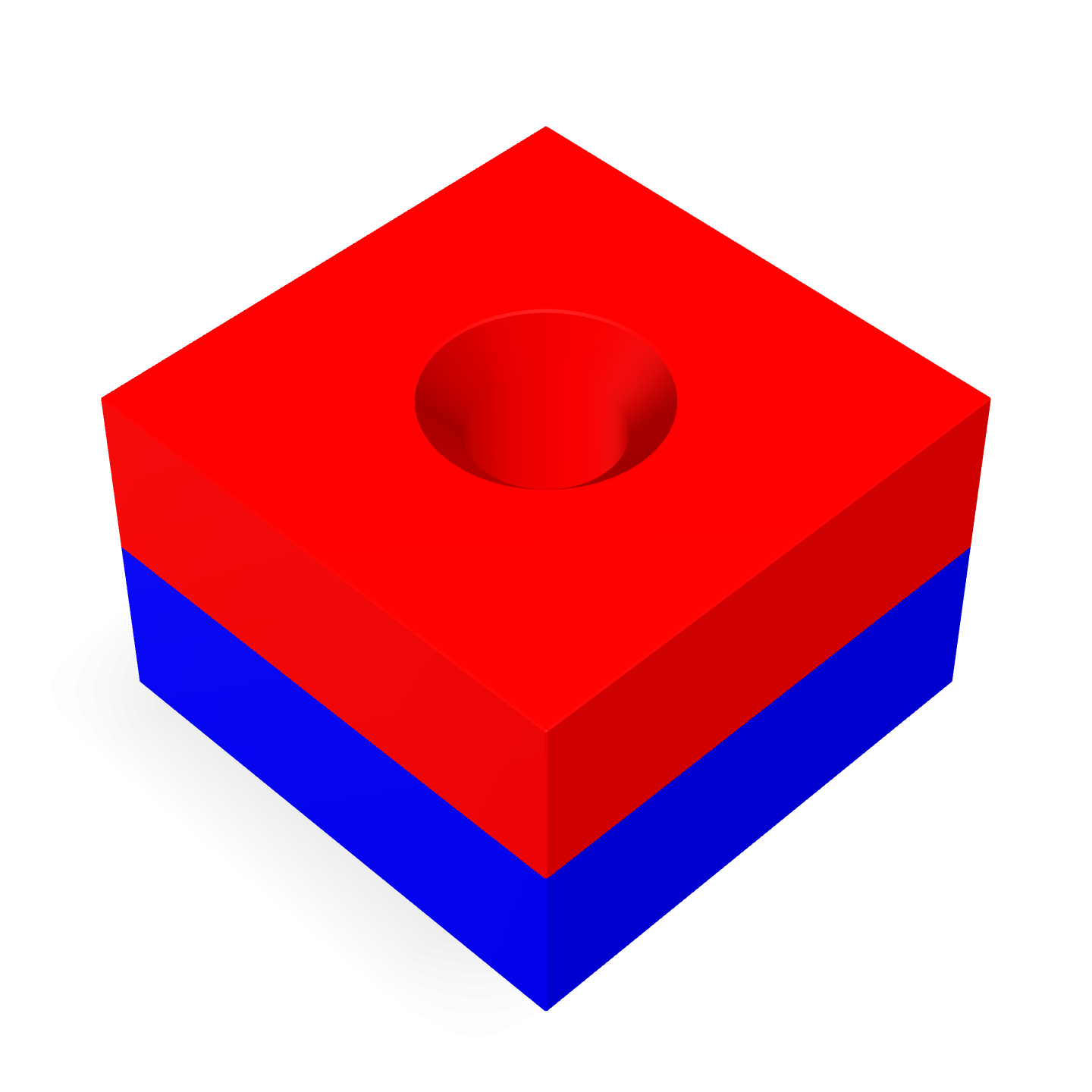

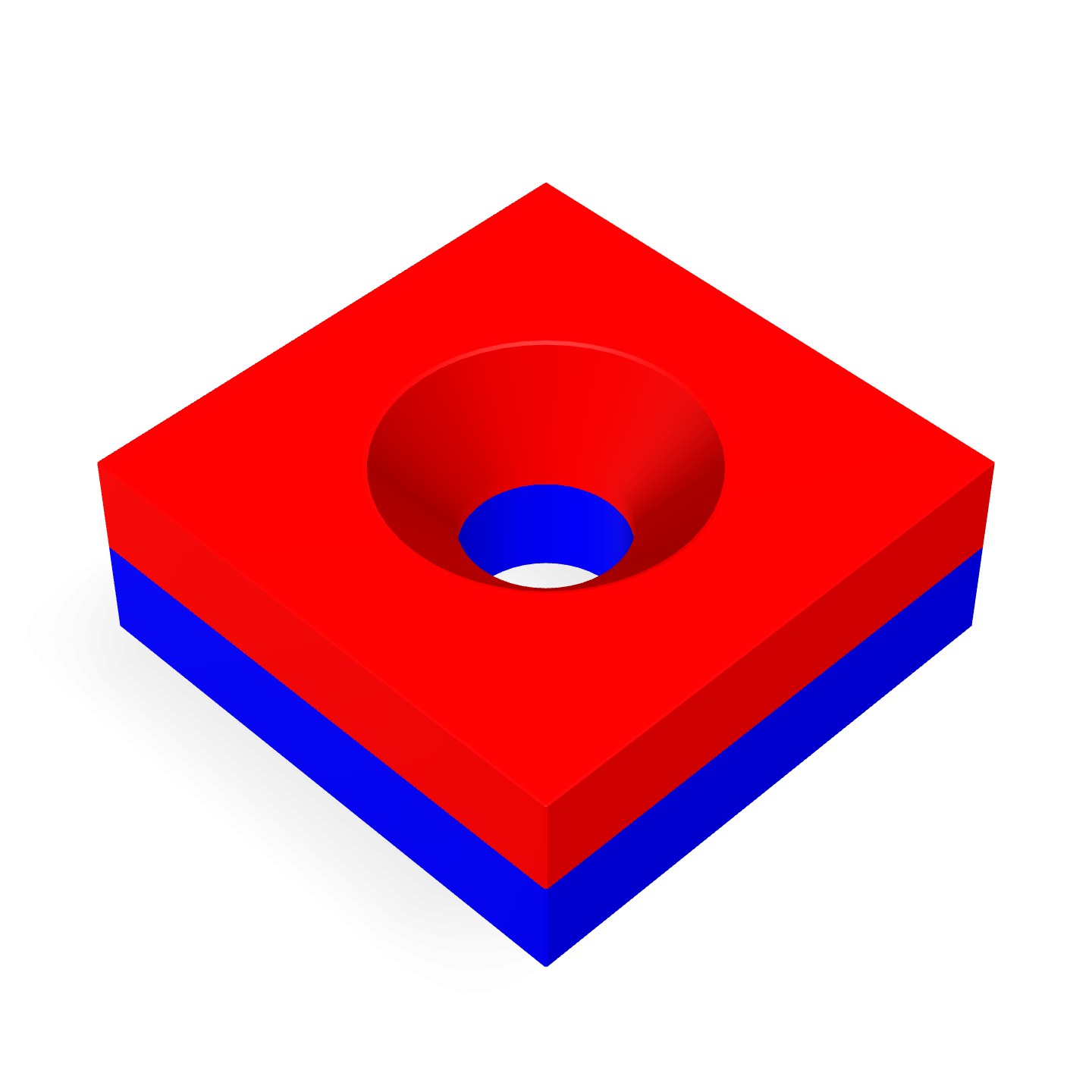

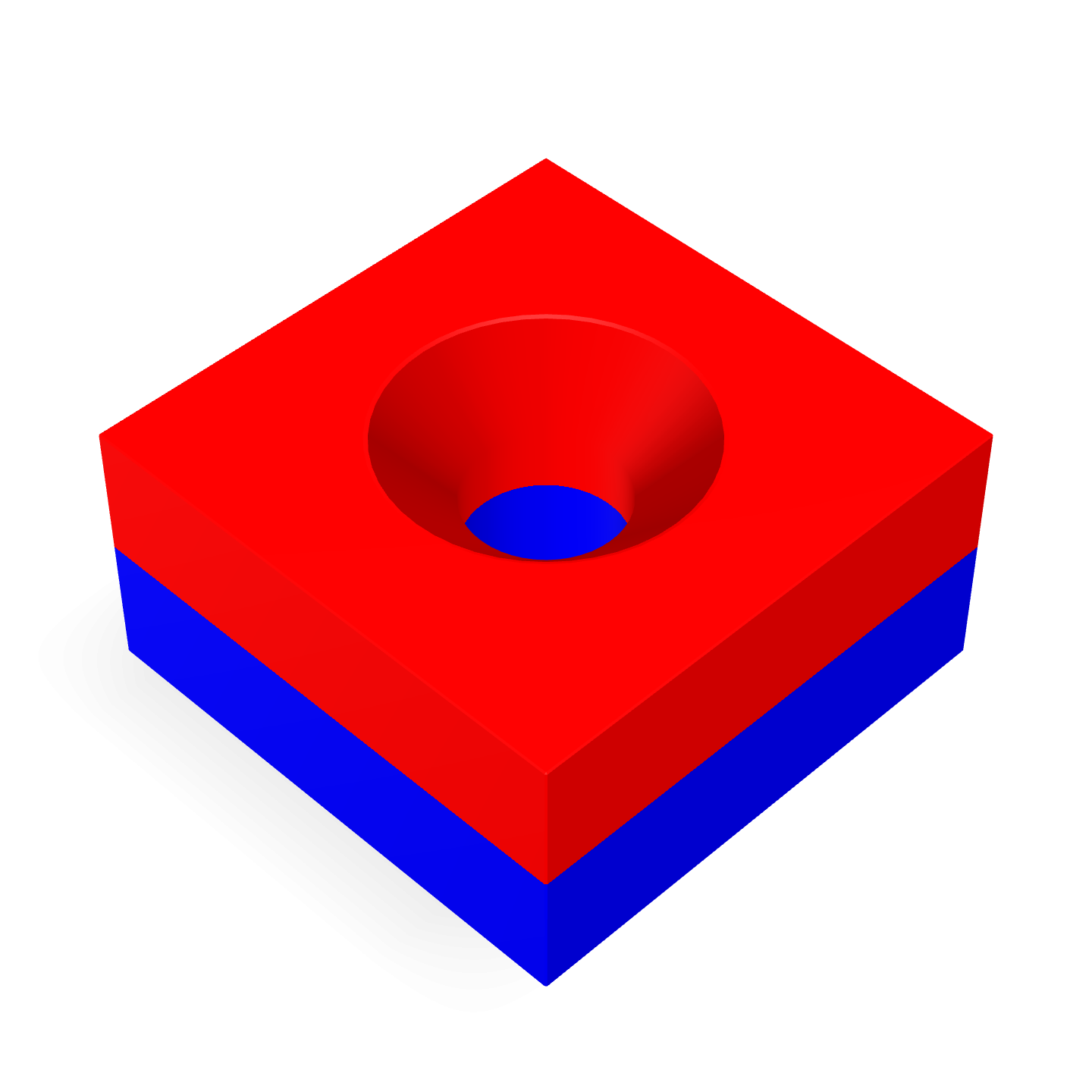

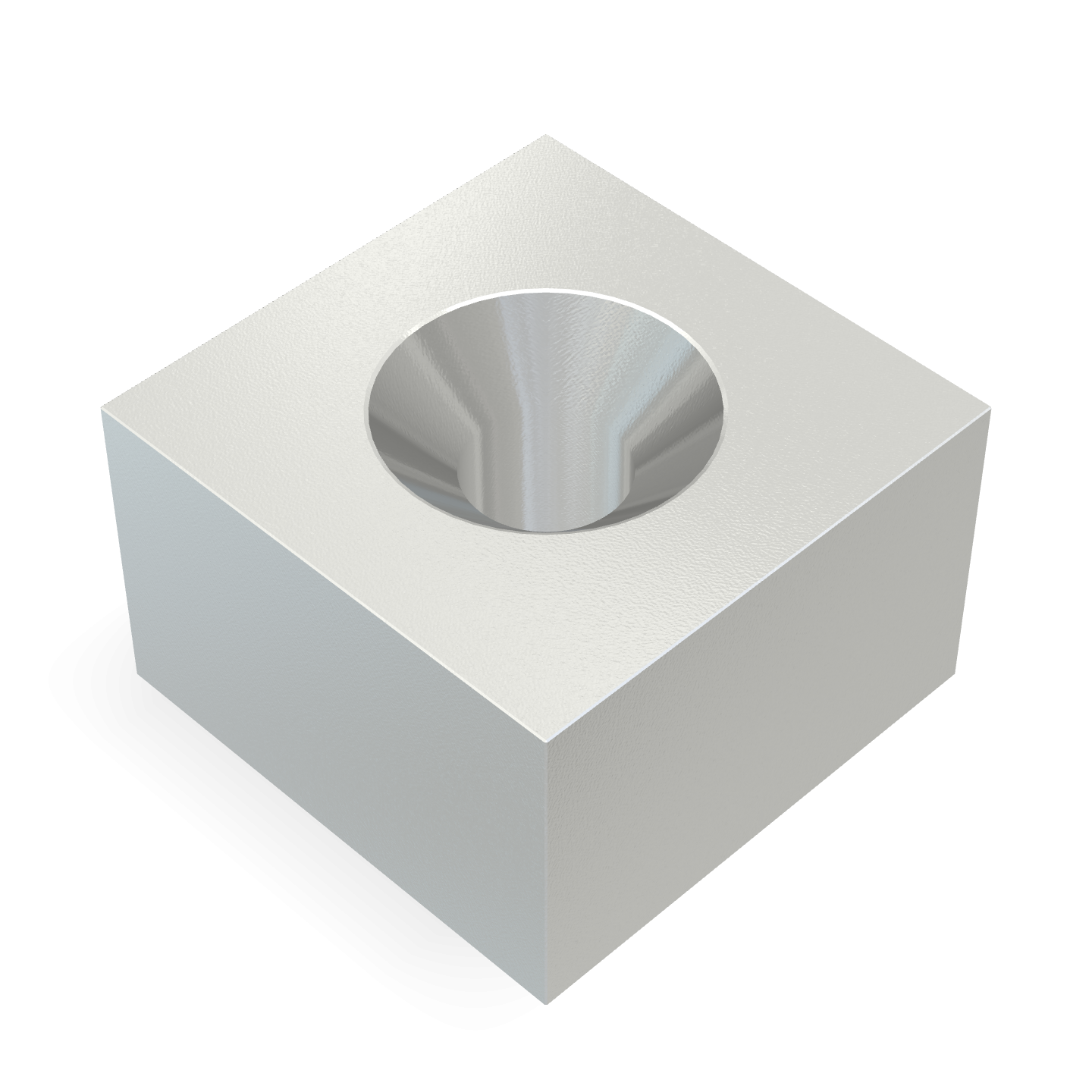

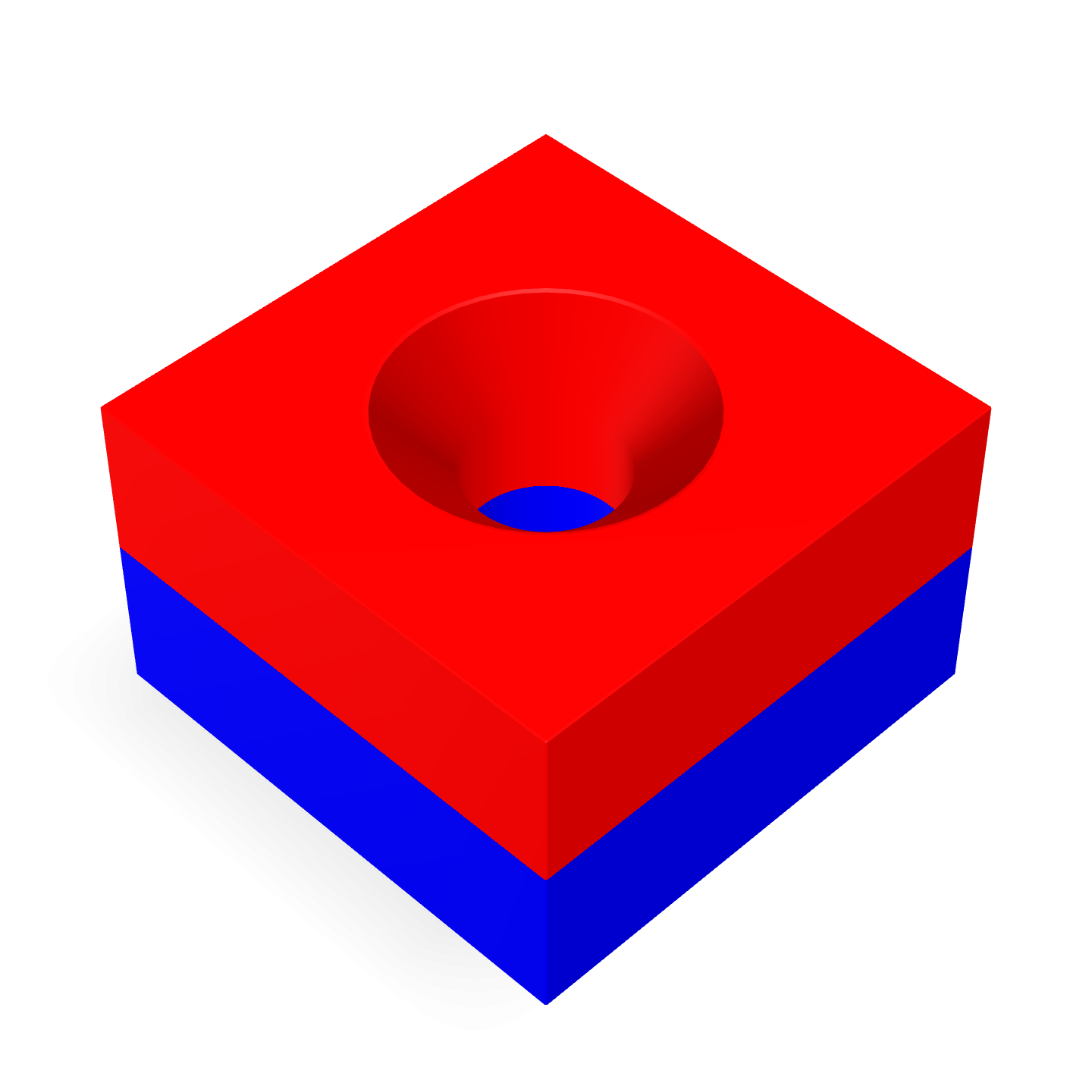

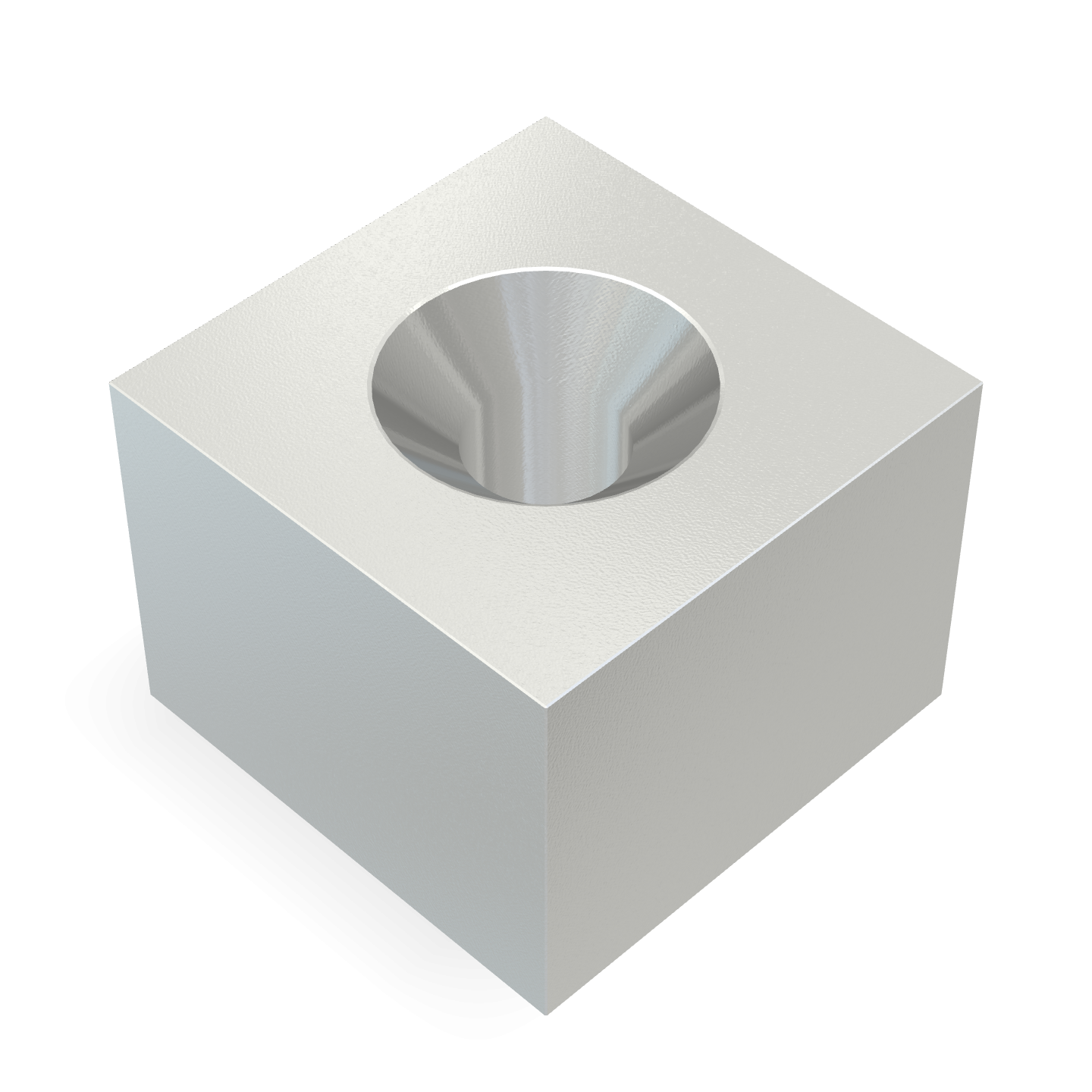

Countersunk block magnets are rectangular or square-shaped industrial magnets with a recessed hole in the center. This allows for easy installation using screws, ensuring a secure fit against a surface. Made from high-strength neodymium, they provide a powerful hold while maintaining a low profile.

Advantages of Countersunk Block Magnets

- Effortless Installation: No need for adhesives—securely fasten with screws.

- High Magnetic Strength: Neodymium composition ensures exceptional holding power.

- Durability: Coated with nickel or epoxy for corrosion resistance.

- Versatile Applications: Ideal for industrial, automotive, woodworking, and DIY projects.

- Flush and Clean Look: Countersunk design allows components to be fastened securely without protrusions.

Common Applications

1. Industrial Machinery

Manufacturers use countersunk block magnets to secure metal parts in assembly lines, robotics, and automated systems. Their ability to stay firmly in place under high vibration and stress makes them indispensable in many industrial setups.

2. Home and Office Use

They are popular in furniture making, hidden latches, tool organization, and door mechanisms. Homeowners and DIY enthusiasts use them in custom shelving, hidden compartments, and various creative projects.

3. Automotive and Aerospace

These magnets offer lightweight yet powerful fastening solutions for vehicle panels, dashboards, and aircraft interiors. Their ability to hold components securely while being easy to remove and reposition makes them ideal for these applications.

4. Retail and Display Fixtures

Retailers and exhibition designers use countersunk block magnets to create modular and adaptable displays. Their ability to hold signs, panels, and fixtures securely while allowing quick changes makes them an excellent choice for commercial environments.

How to Select the Right Countersunk Block Magnet

- Size and Shape: Match the magnet dimensions to your mounting surface.

- Coating: Choose nickel or epoxy coating for added protection.

- Pull Strength: Ensure it meets your holding force requirements.

- Operating Temperature: Consider environmental conditions if using in high-heat applications.

Browse our collection of magnets in Canada to find the perfect countersunk block magnet for your application.

Frequently Asked Questions

What makes countersunk block magnets different from standard magnets?

Their pre-drilled hole allows for secure screw mounting, making them more practical for structural applications.

Are these magnets strong enough for industrial use?

Yes, neodymium countersunk block magnets provide exceptional holding power for heavy-duty applications.

Can these magnets be used outdoors?

Yes, but a corrosion-resistant coating like nickel or epoxy is recommended for long-term outdoor use.

What size screws should I use with countersunk block magnets?

The screw size depends on the diameter of the countersunk hole. Typically, M3 to M5 screws are compatible with most sizes.

How do I remove a countersunk block magnet once installed?

If you need to remove the magnet, carefully unscrew it while applying minimal force to avoid damaging the mounting surface.