Custom Neodymium Magnets in Canada: The Ultimate Guide

In the world of industrial manufacturing, neodymium magnets have become indispensable. These powerful magnets, made from rare-earth materials, are revolutionizing industries across Canada. At Magfine, we specialize in providing custom neodymium magnet solutions tailored to the unique needs of Canadian businesses. This comprehensive guide will explore everything you need to know about custom magnets in Canada, their applications, and why Magfine is the trusted choice for industrial magnet solutions.

What Are Neodymium Magnets?

Neodymium magnets, often referred to as NdFeB magnets, are the strongest type of permanent magnets available today. They are composed of neodymium, iron, and boron, creating a magnetic field that far surpasses traditional ferrite or alnico magnets. Their exceptional strength-to-size ratio makes them ideal for applications where space and weight are critical factors.

Why Choose Custom Neodymium Magnets?

- Precision Engineering: Tailored to exact specifications for optimal performance

- Enhanced Durability: Custom coatings for corrosion resistance in harsh environments

- Cost Efficiency: Reduced material waste through precise manufacturing

- Improved Performance: Optimized magnetic fields for specific applications

Applications of Neodymium Magnets in Canadian Industries

Custom industrial magnets are transforming various sectors in Canada. Here are some key applications:

- Renewable Energy: Wind turbine generators and solar tracking systems

- Automotive: Electric vehicle motors and sensors

- Medical Technology: MRI machines and surgical instruments

- Manufacturing: Robotics and automated assembly lines

- Electronics: Speakers, hard drives, and sensors

- Aerospace: Navigation systems and satellite components

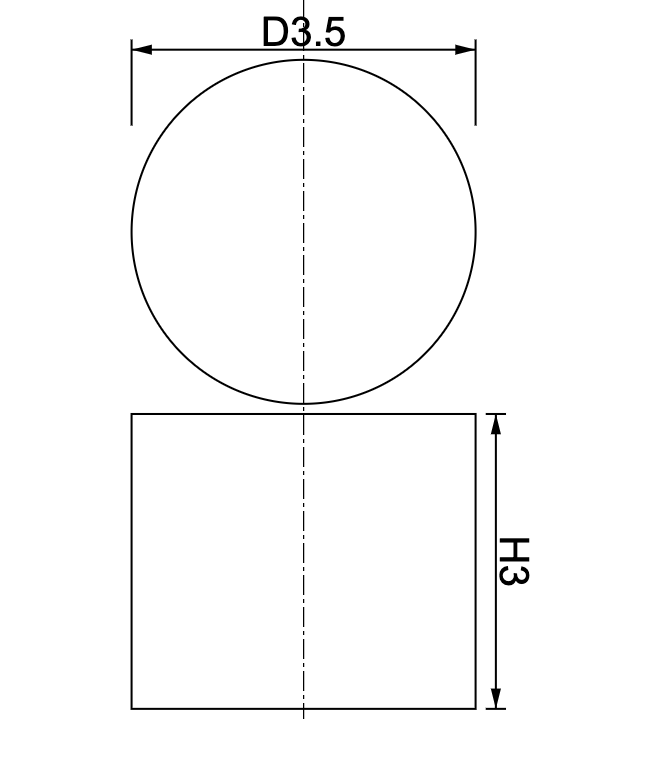

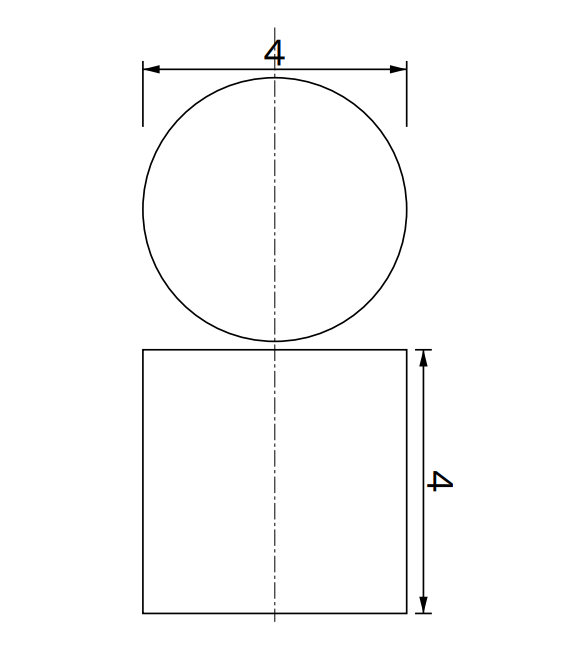

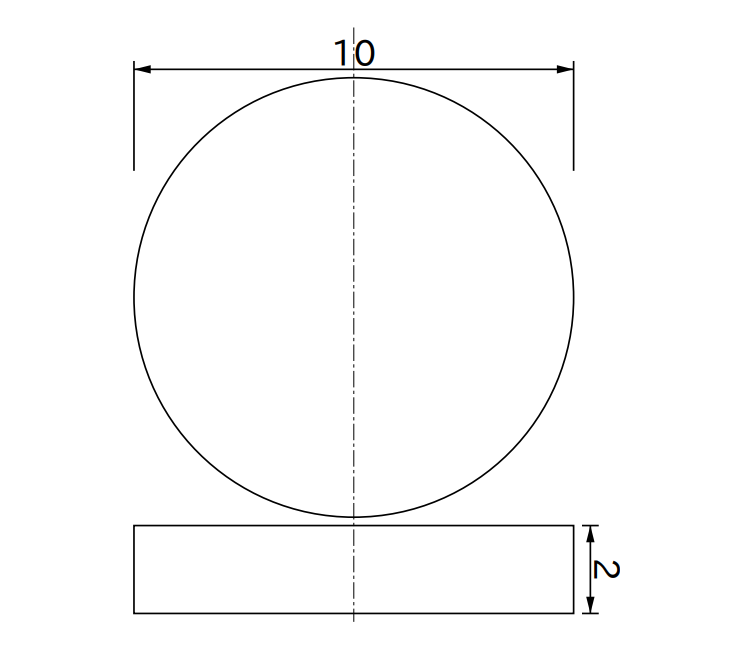

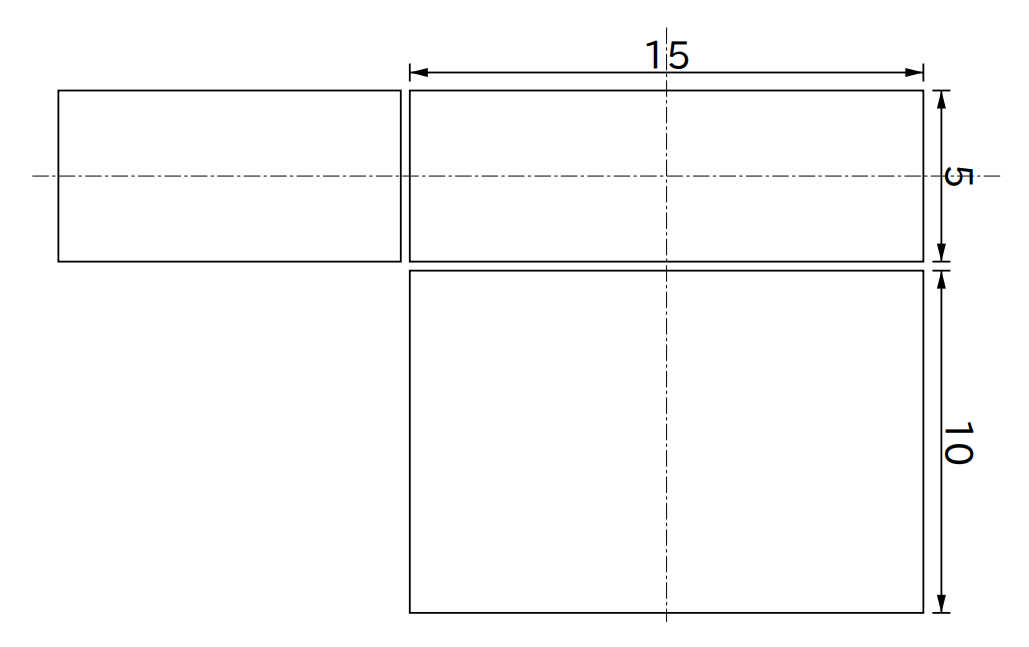

Technical Specifications

Our custom neodymium magnets are engineered to meet the highest standards. Here are the key specifications:

| Parameter | Range | Testing Standard |

|---|---|---|

| Magnetic Strength | N35 to N52 grades | ASTM A977 |

| Temperature Range | -50°C to +200°C | MIL-STD-202 |

| Coating Options | Nickel, Zinc, Epoxy, Parylene | ISO 2178 |

| Tolerance | ±0.005" | ISO 2768-f |

Benefits of Custom Magnets for Canadian Businesses

Choosing custom magnets in Canada offers numerous advantages:

- Local Manufacturing: Faster turnaround times and reduced shipping costs

- Climate-Specific Design: Optimized for Canada's diverse weather conditions

- Regulatory Compliance: Meets all Canadian safety and quality standards

- Technical Support: Direct access to engineering expertise

Design Considerations for Canadian Applications

When designing custom industrial magnets for Canadian use, several factors must be considered:

- Temperature Extremes: Materials must withstand both extreme cold and heat

- Corrosion Resistance: Protective coatings for humid or coastal environments

- Mechanical Stress: Durability for high-vibration applications

- Regulatory Requirements: Compliance with Canadian safety standards

Why Choose Magfine?

As a leading Canadian manufacturer of neodymium magnets, Magfine offers:

- In-house engineering and manufacturing

- Rapid prototyping services

- Competitive pricing with no hidden fees

- Complete quality control and traceability

Frequently Asked Questions

Q: What industries do you serve?

A: We provide custom magnet solutions for industries including renewable energy, automotive, medical, and manufacturing.

Q: Can you match existing magnet specifications?

A: Yes, we can reverse-engineer and replicate existing magnet designs with precision.

Q: What's your minimum order quantity?

A: We accommodate both small prototype orders and large production runs.

Q: Do you provide technical support?

A: Our engineering team is available to assist with design and application challenges.

Start Your Custom Magnet Project Today

Whether you need a prototype or full production run, Magfine delivers magnets in Canada that outperform. Get your instant quote online or speak with our engineering team to discuss your specific requirements.